Gas Treating Services

Amine Plants

Amine treating sweetens sour gas by removing Carbon Dioxide (CO2) and Hydrogen Sulfide (H2S) from the gas stream.

- Improves gas marketability

- Eliminates penalties paid for delivering gas outside required specification

- Reduces damage and enhances longevity of downstream equipment

- Our plants represent decades of experience in designing, constructing and operating gas treating facilities.

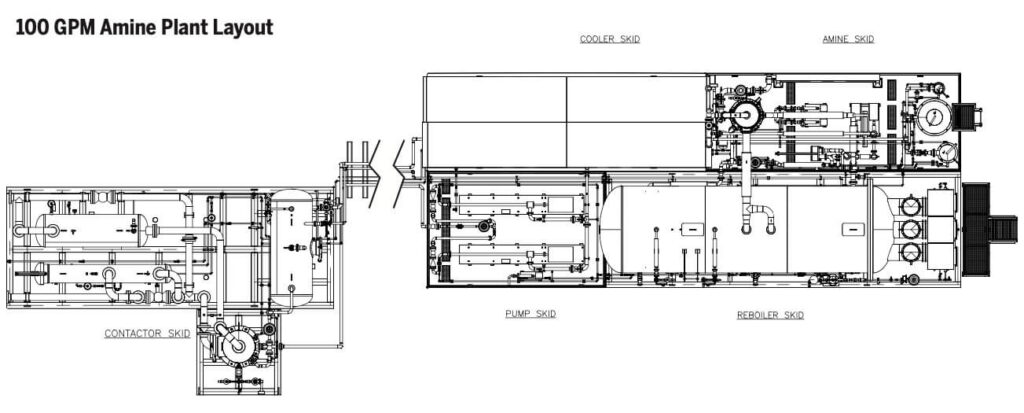

- Plants range in size from 12 GPM to 300 GPM

- Multiple size front ends available depending upon gas composition

- Modular, skid-mounted units for rapid installation and commissioning

- Turnkey solution, including all upstream and downstream ancillary equipment, is available

- “All-in” monthly rate

- Monthly rate with installation and demobilization charge

- Flow rate based pricing

- Our field staff tracks plant performance and identifies operational issues before they become a problem

- Remote emergency shutdown capability

- Ability to monitor customer specific data at customers option including performance and maintenance records.

Gas Cooling

Coolers

Gas/Liquid Coolers reduce the temperature of the process fluid by running it through an air-cooled fin-fan heat exchanger.

Equipment features include:

- Intrinsically safe design mitigates risks associated with open belts, sheaves and other moving parts

- Units designed to maximize uptime and reduce total cost to customers

- Skid mounted for rapid delivery and re-deployment

- Self contained power source eliminates need for external power

- Stainless cooler tubes to reduce corrosion and flaking into the gas stream

- High performance, low noise design reduces noise level by approximately 20 decibels from industry standard designs

- Wheel fin design on tubes offers 10-30% greater heat transfer than a conventional fin. More efficient design reduces power needs and package footprint

- Two modular sizes allows for downsizing of coolers as production decreases

- Full Turnkey Solution – Kodiak will install, commission, operate, maintain, and demobilize our coolers at your site

- Cooler Rental – If you have your own operations team, Kodiak offers coolers for rent

Mechanical Refrigeration Units

Mechanical Refrigeration Units (MRUs) use a chilled medium to condense natural gas liquids (NGLs) from the process gas stream.

- Creates value uplift by extracting NGLs from the gas stream

- Reduce BTU value of process gas to meet pipeline specifications

- Eliminates penalties paid for delivering gas outside required specification

- Rapid deployment to bring gas and liquids on line as quickly as possible

- Can be used as a temporary solution in existing facilities to manage a peak level of production or alleviate bottlenecks

- Provides early stage capacity while permanent facilities are put into place

Joule-Thomson (J-T plants)

A Joule-Thomson plant is a self-refrigeration process that uses a drop in gas pressure to cause a gas to chill. The plant condenses heavy hydrocarbons out of the gas to meet pipeline specifications while removing excess liquids. These liquids are recovered and stored into other salable hydrocarbons such as propane, butane, and natural gasoline.

Gas Treating Services

Dehydration Units

TEG (Triethylene Glycol) Dehydration Units dehydrate gas streams through a regeneration process that removes water from a saturated gas stream. These are typically used downstream of amine treating and other wellhead applications upstream of midstream pipeline connections and fuel connections.

- Reduces damage and enhances longevity of downstream equipment

- Improves quality of gas used in gas engines and other applications

Comprehensive Solutions

Kodiak offers customers comprehensive solutions for treating and conditioning gas from the wellhead to the pipeline.

Our experienced and dedicated team works with your organization to engineer solutions that will maximize gas flow and meet pipeline specifications. We complement your team. Our team works hard to understand your production strategy so you can focus on the aspects of your business that are important to you.

Our comprehensive solutions strategy includes:

- Working closely with our customers to understand their needs, timing, and constraints

- An engineered solution, not just a product offering

- Safe, optimally designed equipment based on years of experience installing and operating gas conditioning and processing equipment

- Installation and commissioning

- A fleet of complementary equipment available to meet our customer’s needs

- Modular, skid mounted equipment for rapid deployment and installation

- Flexible contracting models including sale, lease, and contract operations