PRODUCTION ENHANCEMENT

Production Enhancement

Maximize your return on assets by optimizing production from your mature oil and gas wells with the industry-leading production enhancement compressor package.

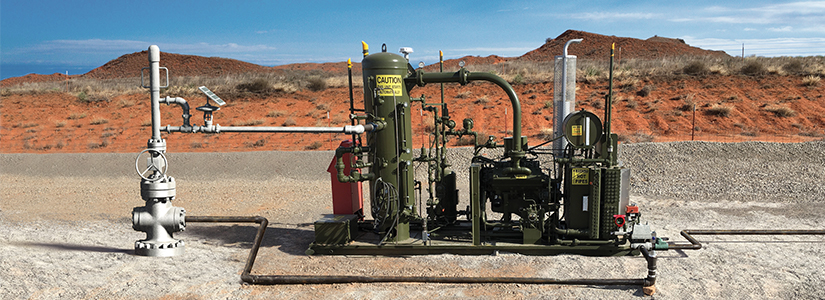

The GasJack® compressor package is a compact yet versatile production enhancement wellhead compressor package, designed to enhance your production and increase profits from oil and natural gas wells, especially marginal wells and those producing from highly permeable formations.

Handling up to 650 mcf/d (18,000 m3/d) of gas per day, the GasJack compressor comes either skid- or trailer-mounted and features flexible-hose connections, simplifying installation with minimal site prep allowing production gains soon after startup. Powered by four cylinders of the integral V8 design, the GasJack compressor is rugged, low-maintenance, and long-lasting—a cost-efficient solution to increase recoverable reserves and extend the life of your wells.

Kodiak Gas Services offers two GasJack models in addition to the electric motor driven VJack. Options include the low-pressure FI unit, and the medium-pressure MP unit, both widely used across North America, Canada and Latin America. The GasJack is also configurable with features for use in either temperate or artic cold climates.

GasJack Compressor Benefits

- Extends the life of mature and low-pressure wells

- Increases flowrate while decreasing wellhead pressure

- Reduces liquid loading to maintain productive flowrate

- Separates fluid efficiently, even in vacuum, without additional wellhead equipment

- Reduces annular and bottomhole pressures to improve flow from reservoir into the well

- Single unit can optimize liquid and gas handling of multiple wells at the same time

GasJack Compressor Standard Features

- 80 BPD blowcase (12.5 m3/d) with 2-in. dump line

- Oversized after-cooler—3-row, air-cooled, and ASME-coded—with a direct-drive nonmetal fan and steel header with access plugs for easy cleaning

- Integral engine-compressor based on industrial V8 design (4 cylinders for power, 4 cylinders for compression in shared block and common crankshaft) with IMPCO natural-gas carburetor, balanced cast-steel crankshaft, and hypereutectic aluminum-alloy pistons, each fitted with four specialized rings to inhibit fluid and gas blow-by into the crankcase

- Integral concentric compressor valves with both suction and discharge plates in each valve, cooling the inner diameter with suction gas and the outer diameter with the engine’s water jacket.

- Automatic oil-level controller with 15-gal.(60 liter) day tank

- ASME-coded pressure vessels with pressure-relief valves

- Weatherproof control panel

- Connections for test gauges

- Manual bypass valving to ease startup and compression blowdown

- Skid- or trailer-mounted with environmental rail and drain connections

Electric Compression

Based on our successful GasJack® compressor package, the electric VJack compressor package fulfills the market need for an even more environmentally friendly natural-gas compressor.

Powered by an electric motor instead of a gas-fueled V8 engine, the VJack compressor excels at oil-well casing-head gas applications.

VJack Package Benefits

- Zero engine emissions

- Low maintenance

- Supports casing-head, plunger-lift and vapor recovery applications

- Corrosion-resistant steel and aluminum parts – no brass alloys

- Corrosion-resistant Viton seals

VJack Package Features

- Quincy QRNG 4125 4-cyl. or QRNG 270 2-cyl. compressor

- 40 HP (37.3 kW) (w/ QRNG 4125) or 20 HP (18.65 kW) (w/ QRNG 270) electric motor

- 50-BPD (8 m3/d) blowcase (to tank)

15-gal. (60 liter) oil makeup tank - ASME-coded pressure vessels

- 2-in. recirculation line

- Weatherproof control panel

- Connections for test gauges

- Customer connection to vent crankcase and gas unloader to a safe area

- Manual bypass valving to ease startup and compression blowdown

- Skid- or trailer-mounted with environmental rail and drain connections

Artificial Lift

Enhance your artificial lift programs with Kodiak Gas Services' GasJack® compressor.

The GasJack compressor can significantly enhance production when used to complement your artificial lift programs and delivers superior efficiencies in plunger lift and rod pump applications. Kodiak’s unique backside auto-injection systems provide automation to further maximize your efficiencies and production enhancement.

GasJack Compressor + the Backside Auto Injection System (BAIS)

The BAIS is a pioneering GasJack compressor configuration to efficiently unload and deliquefy wells to boost production. The system monitors well pressure and redirects gas flow into the annulus when pressure drops below critical flowrate, indicating a buildup of liquid in the wellbore. The redirected gas increases the gas/liquid ratio and lifts the liquid to the surface. The GasJack compressor’s blowcase then separates the liquid and discharges it to a tank or sales line according to customer requirements. When the well’s productive flowrate is restored, the system automatically redirects the gas back to the sales line. Additionally, the BAIS can replace conventional rod-and-pump systems that experience high maintenance costs due to parted rods, pump failure, gas lock, and other problems.

GasJack Compressor + BAIS Features & Benefits

- Can be easily installed on a standard GasJack compressor package

- Non-invasive, easy to install, and inexpensive to test

- Can replace a conventional rod-and-pump system

- Injects only enough gas into the annulus to restore productive flowrate

- Injects up to 475 PSIG (3,300 kPa) into the annulus during the injection cycle

- Allows for on-the-fly adjustments to operating pressures

- Increases liquid-handling capacity with optional gravity-feed vessel

GasJack Compressor + Gas-Assisted Plunger Lift (GAPL)

The GasJack compressor is ideal for gas-assisted plunger lift applications. A GasJack–GAPL package configuration automatically reduces tubing pressure to optimize plunger arrival and after-flow and decreases flowing bottomhole pressure to optimize gas lift. It can also be set up to run in recycle mode during plunger shut-in, and even transform a plunger application from conventional to continuous for high-volume wells. Combining the GasJack-GAPL package configuration with our proprietary BAIS further enhances operational efficiency and production.

GasJack + GAPL Features & Benefits

- Combines the benefits of gas-lift and plunger-lift in a single system

- Greatly enhances plunger-lift applications

- Reduces gas injection in gas-lifted wells

- Increases production from wells experiencing a decline in plunger-lift effectiveness

- Keeps tubing clear of scale and paraffin buildup

Casing Gas

A common challenge with production from low-pressure formations is annulus and bottom-hole pressures that are too high, hindering flow from the reservoir into the wellbore.

The GasJack® compressor reduces annulus and bottomhole pressures, increasing flow from the reservoir. The GasJack compressor is a cost effective solution to increase rod pump efficiencies by reducing gas interference and improving pump fillage. An alternative to flaring gas to maintain low annulus pressure, this application compresses the annular gas up to the necessary pressure and into the sales line.

Benefits of Casing Pressure Reduction

- Reduces back pressure on the formation to enhance hydrocarbon flow into the wellbore

- Improved rod pump efficiencies through better pump fillage

- Reduces pressure on the tubing and allows the liquid to be removed with less pumping system horsepower.

- Allows for acceleration of rod pump speed to increase production

- Lower operating costs by reducing pump failures from fluid pound and gas interference

- Captures annular gas and compresses it into the sales line

- Eliminates the wasteful practice of flaring annular gas

Plunger Lift Assist

The GasJack® compressor is a cost-effective solution for enhancing your plunger lift system efficiency.

The GasJack is synced with the plunger lift system to maximize plunger runs, increasing produced gas and liquid volumes. When the well opens to run the plunger, the GasJack reduces the tubing pressure, helping the plunger travel to the surface. When the plunger reaches the surface, liquid is unloaded and “after flow” begins with the GasJack continuing to reduce the flowing tubing pressure. If operating on a single well, the GasJack’s auto start feature can be enabled to allow the compressor to shut down when the well closes to drop the plunger and will automatically start when the well reopens. When assisting multiple wells, the GasJack has an auto-recycle feature to maximize efficiencies between multi-well plunger runs.

Plunger Lift Assist Benefits

- Less shut-in time required for build-up of pressure

- Longer after-flow

- More cycles per day

- More fluid per run

Vent Gas Management and Vapor Recovery

Capturing hydrocarbon vapor and processing it into a sellable product is now standard practice due to safety concerns, regulation of emissions, and the aversion to flaring, especially near residential areas.

Kodiak Gas Services offers a vapor-recovery unit that captures production and storage-tank vapor and routes it through gas-processing equipment and into the sales line.

Vapor Recovery Features & Benefits

- Low monthly cost instead of large capital expense

- Additional revenue from the sale of gas rather than flaring or incineration

- Handles gas volumes of 21-335 mcf (600–9,500 cubic meters) per day

- Discharges up to 250 PSIG (1725 kPa) at zero static pressure

- Skid- or trailer-mounted and self-contained for easy installation

- Powered by natural gas, eliminating the need for a secondary fuel source

- Enables gas recycling (measured in ounces) for longer run-times

- Adjustable speed and volume control for optimal performance

- Designed for Class 1, Division 2 hazardous locations